Description

The steam engine is a heat engine that performs mechanical work using steam as its working fluid. This revolutionary technology represents a critical advancement in power generation, enabling the conversion of heat energy into mechanical motion on a scale previously unattainable. The development of the steam engine was a pivotal moment in human history, powering the Industrial Revolution and fundamentally changing how work is performed.

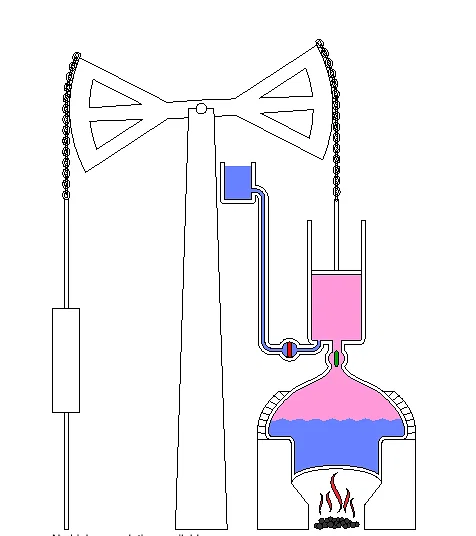

Diagram of Thomas Newcomen's atmospheric steam engine (1712), showing the basic operating principles

Practical Guide to Steam Engines

1. Understanding Steam Power Principles

Before attempting to build a steam engine, it's essential to understand the basic principles that make it work:

- Thermal expansion: When water is heated to steam, it expands approximately 1,700 times in volume

- Pressure generation: When steam is contained, it creates pressure that can be harnessed

- Vacuum formation: When steam condenses back to water, it creates a partial vacuum

- Energy conversion: Heat energy from combustion is converted to mechanical energy through steam expansion and pressure

2. Types of Steam Engines

A. Atmospheric (Newcomen) Engine

The simplest type of steam engine to construct, using atmospheric pressure as the primary driving force:

- Operating principle: Steam fills a cylinder, then condenses to create a vacuum, allowing atmospheric pressure to push a piston down

- Key components:

- Boiler for generating steam

- Cylinder and piston assembly

- Injection system for cooling water

- Beam and connecting mechanisms

- Valves for controlling steam and water flow

- Efficiency: Very low (less than 1% thermal efficiency), but functional

- Best applications: Water pumping, especially from mines

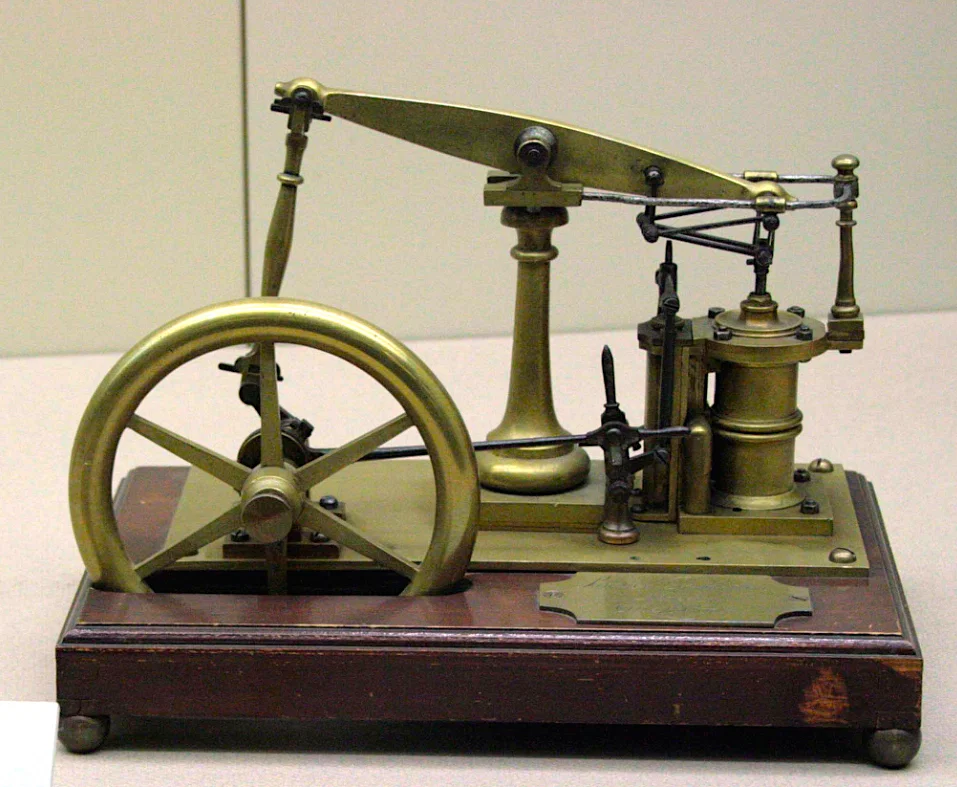

B. Watt-Type Engine

An improved design that separates the condensation process from the working cylinder:

- Operating principle: Steam expands in a cylinder, then is directed to a separate condenser, maintaining cylinder temperature

- Key improvements over Newcomen:

- Separate condenser (prevents cylinder cooling)

- Steam jacket around cylinder (maintains temperature)

- Double-acting design (steam pushes piston in both directions)

- Parallel motion mechanism (converts linear to rotary motion)

- Efficiency: 2-5% thermal efficiency (significant improvement)

- Best applications: Rotary motion for mills, factories, and early transportation

Model of James Watt's rotary steam engine design, showing the flywheel and connecting mechanisms

3. Building a Basic Atmospheric Steam Engine

This guide focuses on constructing a simplified Newcomen-type atmospheric engine, which is achievable with the technologies available at this tier.

A. Materials Required

- For the boiler:

- Copper or iron sheet (minimum 3mm thickness)

- Rivets or bolts for assembly

- Clay or other sealant material

- Pressure release valve (simple weighted design)

- For the cylinder and piston:

- Cast iron cylinder (carefully bored to uniform diameter)

- Piston (slightly smaller than cylinder with leather or hemp sealing)

- Lubricant (animal fat or vegetable oil)

- For the beam and linkages:

- Hardwood beam (oak or similar, 2-3 meters long)

- Iron chains or rods for connections

- Pivot point (iron axle and bearings)

- For valves and piping:

- Copper or iron pipe

- Simple flap valves or plug valves

- Water injection system (small tank and pipe)

- Tools needed:

- Metal cutting tools

- Drilling equipment

- Forge for heating and shaping metal

- Precision boring tools for cylinder

- Measuring instruments

B. Boiler Construction

- Design considerations:

- Aim for a cylindrical or spherical shape for even pressure distribution

- Size according to engine needs (approximately 100-200 liters for small engine)

- Include access port for cleaning and maintenance

- Incorporate mounting points for pipes and valves

- Construction steps:

- Cut metal sheets to required dimensions

- Form into cylindrical or spherical shape

- Join edges with rivets or bolts, ensuring tight seal

- Apply sealant to all joints

- Install outlet pipe at top for steam

- Install drain valve at bottom

- Create and install simple pressure relief valve

- Test for leaks using low-pressure steam

- Safety features:

- Pressure relief valve (weighted lever design)

- Water level indicator (simple sight glass or dipstick)

- Thick walls with safety factor of at least 5x expected pressure

- Regular inspection points for metal fatigue

C. Cylinder and Piston Assembly

- Cylinder creation:

- Cast iron cylinder with walls at least 1cm thick

- Bore interior to precise diameter (30-50cm recommended for first engine)

- Polish interior surface to reduce friction

- Create mounting flanges at top and bottom

- Drill holes for steam inlet and water injection

- Piston construction:

- Cast iron disk slightly smaller than cylinder diameter (2-3mm clearance)

- Create groove around edge for sealing material

- Attach leather or hemp packing material soaked in oil

- Install connection point at center for rod attachment

- Ensure piston moves freely but with minimal steam leakage

- Assembly:

- Mount cylinder vertically on stable platform

- Insert piston from top

- Connect piston rod to beam mechanism

- Install top and bottom caps with appropriate seals

- Connect steam inlet pipe from boiler

- Install water injection system for condensing

D. Beam and Connecting Mechanisms

- Beam construction:

- Select straight-grained hardwood beam or fabricate from iron

- Create pivot point at center with iron axle and bearings

- Reinforce beam ends with iron plates

- Install connection points at both ends (for piston and pump/work)

- Balance beam weight for smooth operation

- Connection mechanisms:

- Create chain or rod connections from piston to beam

- Install counterweight on opposite end if not connecting to pump

- Ensure all pivot points have proper lubrication

- Add guide mechanisms to prevent lateral movement

- For rotary motion (optional):

- Connect beam to crank mechanism

- Install flywheel to smooth motion

- Add connecting rod between beam and crank

- Ensure proper counterbalancing

E. Valve and Control Systems

- Steam control valve:

- Create simple plug valve or slide valve

- Connect to manual control lever

- Ensure tight sealing when closed

- Position between boiler and cylinder

- Water injection system:

- Install small water reservoir above cylinder

- Create injection pipe into cylinder

- Add control valve for water flow

- Position spray to maximize condensation effect

- Automatic valve system (advanced):

- Create linkage from beam to valve controls

- Add adjustable timing mechanisms

- Ensure proper sequencing of steam and water

- Include manual override capability

4. Engine Operation and Maintenance

A. Starting Procedure

- Preparation:

- Fill boiler to appropriate level (2/3 to 3/4 full)

- Ensure all valves are closed

- Check all connections and seals

- Lubricate all moving parts

- Fill water injection reservoir

- Firing the boiler:

- Start with small fire, gradually increasing

- Monitor pressure using gauge or relief valve behavior

- Allow system to heat thoroughly (1-2 hours)

- Bleed air from system by briefly opening valves

- Initial cycling:

- Open steam valve to fill cylinder

- Allow cylinder to heat thoroughly

- Close steam valve

- Inject water to condense steam

- Observe piston movement

- Repeat process, adjusting timing as needed

B. Regular Operation

- Maintaining steady operation:

- Keep fire at consistent level

- Monitor boiler water level constantly

- Adjust valve timing for optimal performance

- Listen for unusual sounds indicating problems

- Monitor temperature of bearings and moving parts

- Adjusting power output:

- Control fire intensity to adjust steam production

- Modify steam valve timing

- Adjust water injection amount

- Change operating speed through valve timing

- Shutdown procedure:

- Reduce fire gradually

- Allow pressure to decrease naturally

- Stop engine operation when pressure is low

- Close all valves

- Drain system when cool if not using for extended period

C. Maintenance Requirements

- Daily maintenance:

- Check water levels

- Inspect for leaks

- Lubricate all moving parts

- Clean ash from firebox

- Check valve operation

- Weekly maintenance:

- Inspect all seals and packings

- Check for wear on moving parts

- Clean water injection system

- Tighten any loose connections

- Test safety systems

- Monthly maintenance:

- Clean boiler if water quality is poor

- Inspect cylinder and piston for wear

- Check beam and connections for cracks

- Rebuild any worn valve components

- Inspect foundation and mounting points

5. Advanced Improvements

A. Watt-Style Improvements

- Separate condenser:

- Create vessel connected to cylinder but separate from it

- Install water cooling system around condenser

- Add valve to direct steam from cylinder to condenser

- Include air pump to remove non-condensable gases

- Double-acting cylinder:

- Modify cylinder to allow steam entry at both ends

- Create sealed piston rod passage

- Install valves to control steam flow to both sides

- Modify beam connections for push-pull action

- Parallel motion mechanism:

- Create linkage system to convert linear to rotary motion

- Ensure piston rod moves in straight line

- Connect to flywheel and crank system

- Balance all components for smooth operation

B. Efficiency Improvements

- Steam jacketing:

- Create double-walled cylinder

- Direct steam into space between walls

- Insulate outer wall to retain heat

- Add control valve for jacket steam

- Compound expansion:

- Add second, larger cylinder

- Direct exhaust steam from first cylinder to second

- Connect both pistons to same beam or shaft

- Adjust timing for optimal expansion

- Governor system:

- Create centrifugal ball mechanism

- Connect to steam throttle valve

- Adjust weights and spring tension for desired speed

- Include manual override capability

Troubleshooting Common Issues

Insufficient Power

Cause: Low steam pressure; poor vacuum; leaking piston; incorrect timing

Solution: Increase fire intensity; check for air leaks in condenser system; replace piston seals; adjust valve timing

Erratic Operation

Cause: Inconsistent steam supply; valve problems; water level fluctuations; mechanical binding

Solution: Maintain steady fire; clean and repair valves; install better water level control; check and lubricate all moving parts

Excessive Steam Consumption

Cause: Leaking joints; poor cylinder insulation; incorrect valve timing; oversized passages

Solution: Reseal all joints; add insulation to cylinder; adjust valve timing; resize steam passages appropriately

Knocking or Banging Sounds

Cause: Water in cylinder (water hammer); loose components; excessive play in bearings

Solution: Improve drainage; ensure proper steam quality; tighten all connections; replace worn bearings

Boiler Problems

Cause: Scale buildup; corrosion; overheating; poor water quality

Solution: Regular cleaning; use cleaner water sources; maintain proper water level; install better safety systems