Copper Mining and Extraction

Prerequisites:

Parent Technology:

Description

Copper was one of the first metals to be worked by humans. Its relatively low melting point and the visual distinctiveness of its ores made it accessible to early metalworkers. This guide covers the practical methods for locating, mining, and extracting copper using only technologies available in early civilizations.

Ancient copper mine entrance showing early extraction techniques

Identifying Copper Deposits

Visual Identification

Copper ores are often visually distinctive:

- Malachite: Bright green, often in banded patterns

- Azurite: Deep blue mineral, often found with malachite

- Chalcopyrite: Brassy yellow, sometimes with iridescent tarnish

- Native copper: Reddish-brown metallic appearance

- Cuprite: Red to dark red mineral

Where to Look

Copper deposits are typically found in:

- Weathered outcrops: Look for green or blue staining on rock faces

- Stream beds: Native copper nuggets may be found in stream gravels

- Mountainous regions: Particularly in areas with volcanic history

- Contact zones: Where different rock types meet

- Gossan formations: Rusty, oxidized caps above sulfide deposits

Simple Field Tests

- Streak test: Rub the mineral on unglazed porcelain (or a rough stone). Copper minerals often leave distinctive colored streaks.

- Vinegar test: Copper carbonates (malachite, azurite) will fizz when vinegar is applied.

- Flame test: Copper compounds produce a distinctive green-blue flame when heated.

Mining Techniques

Surface Collection

The simplest method is to collect exposed copper ore or native copper from the surface:

- Search areas with visible copper mineralization

- Collect loose pieces of ore from the surface

- Look for pieces washed into streams or exposed by erosion

- Native copper nuggets can sometimes be found in stream beds

Open-Pit Mining

For shallow deposits:

- Clear vegetation and loose soil from the area

- Dig a pit following the visible ore vein

- Use stone hammers and picks to break up the ore

- Create terraces as you dig deeper for stability

- Use baskets or leather bags to remove ore and waste rock

Fire-Setting

For harder rock:

- Build a fire against the rock face containing copper ore

- Maintain the fire until the rock is thoroughly heated

- Quickly douse with cold water to cause thermal shock

- The rapid cooling causes the rock to crack and fracture

- Break apart the weakened rock with stone tools

- Repeat the process to advance deeper into the deposit

Note: Fire-setting creates toxic fumes, especially with sulfide ores. Always work in well-ventilated areas and avoid breathing the smoke.

Primitive Shaft Mining

For deeper deposits:

- Dig a vertical or sloped shaft following the ore vein

- Support the walls with timber frames if available

- Use fire-setting to break up hard rock

- Provide ventilation with fire (creating convection) or fabric fans

- Use a bucket-and-rope system to remove ore and waste

- Mark your path and create regular openings to the surface when possible

Mining Tools

Tools that can be made with earlier technologies:

- Stone hammers: Hard river cobbles or shaped stone heads with wooden handles

- Antler picks: Deer or elk antlers used as digging tools

- Wooden wedges: Hardwood wedges driven into cracks to split rock

- Bone scoops: For removing loose material

- Baskets and leather bags: For transporting ore

- Stone mortars: For crushing ore

Ore Processing

Sorting

Before further processing:

- Visually inspect mined material and separate obvious ore from waste rock

- Look for green, blue, or reddish coloration indicating copper minerals

- Set aside any pieces of native copper for direct working

- Wash the ore if possible to better reveal mineral content

Crushing and Grinding

To prepare for smelting:

- Break larger pieces into smaller chunks using stone hammers

- Grind the chunks into a coarse powder using stone mortars and pestles

- For larger quantities, use a grinding stone or quern

- Aim for particles roughly the size of sand grains

Washing and Concentration

To increase the copper content:

- Place crushed ore in a wide, shallow container

- Add water and swirl gently

- Copper minerals are denser and will settle to the bottom

- Carefully pour off the water and lighter materials

- Repeat several times to concentrate the ore

- Allow the concentrated ore to dry in the sun

Smelting Copper

Building a Simple Smelting Furnace

- Dig a bowl-shaped pit about 30-40 cm in diameter and 20-30 cm deep

- Line the pit with clay, leaving it to dry thoroughly

- Create a small opening at the bottom for air intake

- For better results, build a clay dome over the pit with an opening at the top

- Allow the clay structure to dry completely before use

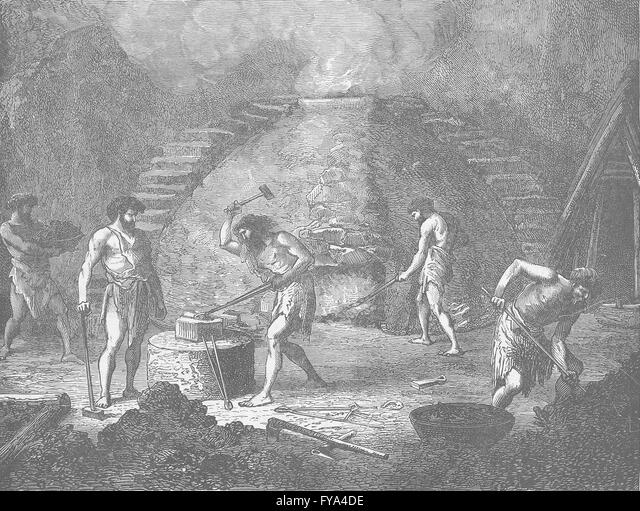

Primitive copper smelting process using a simple furnace

Preparing the Charge

- Mix the concentrated copper ore with charcoal in approximately equal volumes

- If available, add crushed limestone or seashells as flux (about 10% of the ore volume)

- For carbonate ores (malachite, azurite), the ratio can be 1 part ore to 1-2 parts charcoal

- For sulfide ores (chalcopyrite), first roast the ore in an open fire to convert to oxide before smelting

The Smelting Process

- Start a fire in the furnace and allow it to heat up thoroughly

- Add the prepared charge mixture gradually

- Use bellows or blowpipes to increase the temperature (aim for at least 1085°C)

- Continue adding fuel and maintaining airflow for 1-2 hours

- The copper will melt and collect at the bottom of the furnace

- The slag (waste material) will float on top

Recovering the Copper

- Allow the furnace to cool slightly but not completely

- Break open the bottom of the furnace if necessary

- Remove the copper "button" or "prills" (small metallic beads)

- The first smelt often produces impure copper

- For purer copper, re-smelt the recovered metal

Refining

To improve copper purity:

- Create a small clay crucible

- Place the copper from the first smelt into the crucible

- Cover with a layer of charcoal

- Heat until the copper melts completely

- The impurities will either oxidize or form slag on the surface

- Skim off any slag that forms

- Pour the molten copper into a depression in sand or a stone mold

Working with Native Copper

Native copper can be worked directly without smelting:

Cold Working

- Hammer the native copper to flatten it

- Shape as desired using stone hammers and anvils

- Copper will work-harden, becoming brittle

- When it becomes too hard to work, proceed to annealing

Annealing

- Heat the copper in a fire until it glows red

- Allow it to cool slowly

- This restores malleability to the copper

- Repeat the cycle of hammering and annealing as needed

Safety Considerations

- Mining tunnels can collapse - always ensure proper support

- Copper ore dust can be toxic if inhaled - work in ventilated areas

- Fire-setting produces toxic fumes - avoid breathing smoke

- Molten copper can cause severe burns - use extreme caution

- Some copper compounds are toxic - wash hands after handling

Common Challenges and Solutions

Insufficient Temperature

- Problem: Copper not melting during smelting

- Solution: Improve airflow with better bellows or multiple blowpipes, use drier charcoal, insulate furnace better

Poor Copper Recovery

- Problem: Low yield of copper from ore

- Solution: Better ore concentration before smelting, add flux material, ensure proper furnace temperature

Brittle Copper

- Problem: Copper breaks when worked

- Solution: Proper annealing between working sessions, better refining to remove impurities

Mine Ventilation

- Problem: Poor air quality in deeper mines

- Solution: Create air shafts, use fire to create convection currents, use fabric fans

Next Steps

After mastering copper extraction:

- Experiment with alloying copper with tin to create bronze

- Develop more advanced furnace designs

- Create specialized copper tools and implements

- Explore more efficient mining techniques